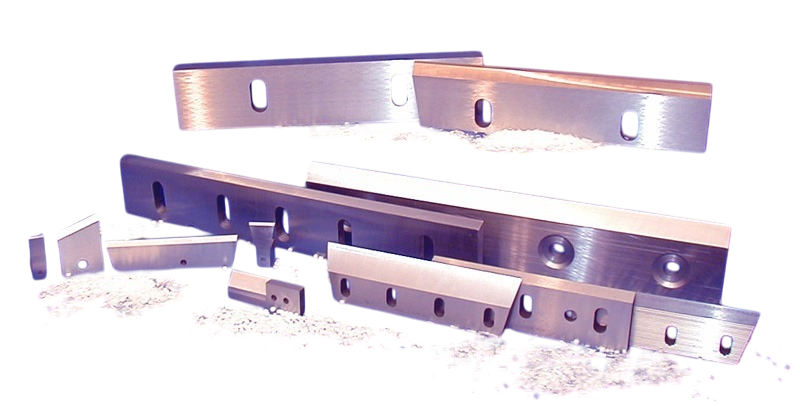

GRANULATOR BLADES

Product Details:

- Usage Industrial

- Shape Rectangle

- Hardness Yes

- Material Stainless Steel

- Size Standard

- Product Type GRANULATOR BLADES

- Color Silver

- Click to View more

GRANULATOR BLADES Price And Quantity

- 2000 INR/Unit

- 5 Unit

GRANULATOR BLADES Product Specifications

- Silver

- Industrial

- Standard

- Stainless Steel

- GRANULATOR BLADES

- Yes

- Rectangle

GRANULATOR BLADES Trade Information

- 2-3 Unit Per Day

- 5 Days

Product Description

Granulator Blades are cutting elements that are highly utilized in the plastics recycling and processing sector to reduce the size and reprocess the material. These cutting tools are expected to provide accurate and consistent cuts in order to transform plastic waste, rubbers, and other resources into uniform granules that are either reused or manufactured again. Made in precision and durability, Granulator Blades make sure that they perform steadily even when fully burdened with constant and high-powered use. These blades are produced with alloy and stainless steels of high grade and are made with the help of the latest heat treatment methods so that they could have the highest possible level of hardness and toughness. Such balance enables the blades to prevail sharp cutting edges, as also to withstand impact, abrasion and fatigue. The outcome is enhanced cutting performance, better machine functionality and increased machine serviceability. Granulator Blades reduce the time spent changing blades and offline time when maintaining them, which results in increased productivity and cost-efficiency among processors.

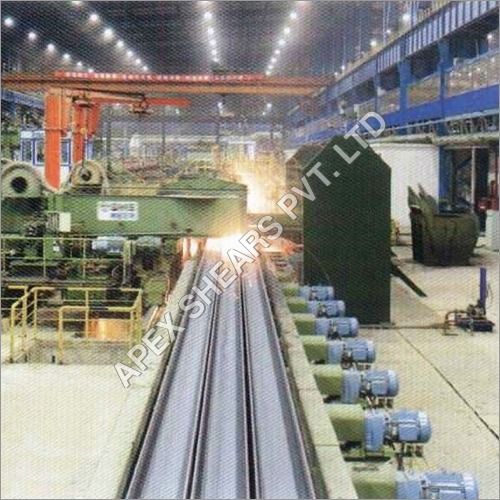

Nature and Uses of Granulator Blades

Granulator Blades are made to fit in plastic granulators and shredding machines that have the materials being cut into smaller and uniform grains. They play a very important role in the recycling plants, injection molding plants, extrusion units, and plastic manufacturing plants. The materials that are processed by these blades include rigid plastics, soft plastics, rubber compounds and industrial scraps among others. The rectangular form is standardized and its dimensions are accurate to fit most of the granulating machines. Their sturdy built enables them to resist numerous cutting cycles, intense mechanical loading and long usage. Granting a uniform size of the granules, Granulator Blades contribute to the enhancement of the efficiency of downstream processing and the general quality of products.

High-Quality Stainless Steel Construction

The Granulator Blades are made out of the high-quality stainless steel and alloy tool steel that was chosen due to excellent mechanical properties. This metal option gives it better resistance to corrosion, wear and thermal stress and the blades are best suited to the long term industrial applications. The blades are sharp and structurally sound even in the most demanding of environments making them reliable in cutting. Accurate machining and monitored grinding operations lead to clean cut and sharp cutting edges that cause less material drag and use less power. The blades have been structured in such a way that they ensure stability of performance even during long periods of operation and thus the cost of energy is minimized.

Designed for Industrial Reliability

The Granulator Blades are made to meet the stringent standards of the industry which make them consistent, accurate and reliable. The blades is heat treated in a controlled manner in order to increase hardness without affecting toughness to enable it to support heavy loads and withstand repeated impact during granulation. Its rectangular shape and standardized size makes installation and replacement of the machine to be easy, and machines do not take very long to be maintained. The blades can also be re-sharpened several times which again increases their service life and provides long term benefits to the plant operators.

Production Process and Quality Control

The production of Granulator Blades follows a meticulous and quality-driven process. It starts by picking the top quality raw materials, then cutting and shaping it with precision. The high-end heat treatment processes are used to attain the desired hardness and edge retention. Once heat treated, each blade is ground to precise specifications to make sure that it is dimensionally accurate and cuts sharp. The last checks involve hardness, surface finish and dimensional checks. This rigorous quality control initiative will make sure that all Granulator Blades will be of high performance quality before they are delivered to the customer.

FAQs:

Where do Granulator Blades find their application in industries?

The Granulator Blades are used in the granulating and shredding machines, to cut plastic, rubber and other materials into homogenous granules to be recycled or fed to other processes.

What is the reason for preferring stainless steel Granulator Blades?

Stainless steel is highly resistant to corrosion and wear and therefore the blades are sharp and maintain their durability even in harsh industrial conditions.

How does Granulator Blades increase granulation efficiency?

They can cut cleanly and uniformly due to their sharp edges that have been ground carefully and trim, use less power, increase uniformity of granules, and generate less stress on machines.

How frequently do you replace or sharpen Granulator Blades?

Depending on the operating conditions and the type of material, replacement is required or sharpened. Frequent inspection aids in recognizing the dullness or wear of the edges and the maintenance can be carried out promptly to keep the performance intact.

Would Granulator Blades work with other machines?

Yes, the rectangular shape is standardized and can easily fit with majority of the granulators and shredding machines. Other sizes may also be customized on need basis.

What are some precautions that are observed when installing a blade?

It is always essential to turn off and isolate the machine when installing it. Wipe off the blade seat, make sure it is properly fixed and fasten all the attachments according to machine requirements to be able to work safely.

What factors influence the lifespan of Granulator Blades?

The life of blades is based on the quality of the material, heat treatment, the speed, processed material and steps taken during the maintenance. Life span of the blades is greatly increased through proper usage and regular sharpening.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+