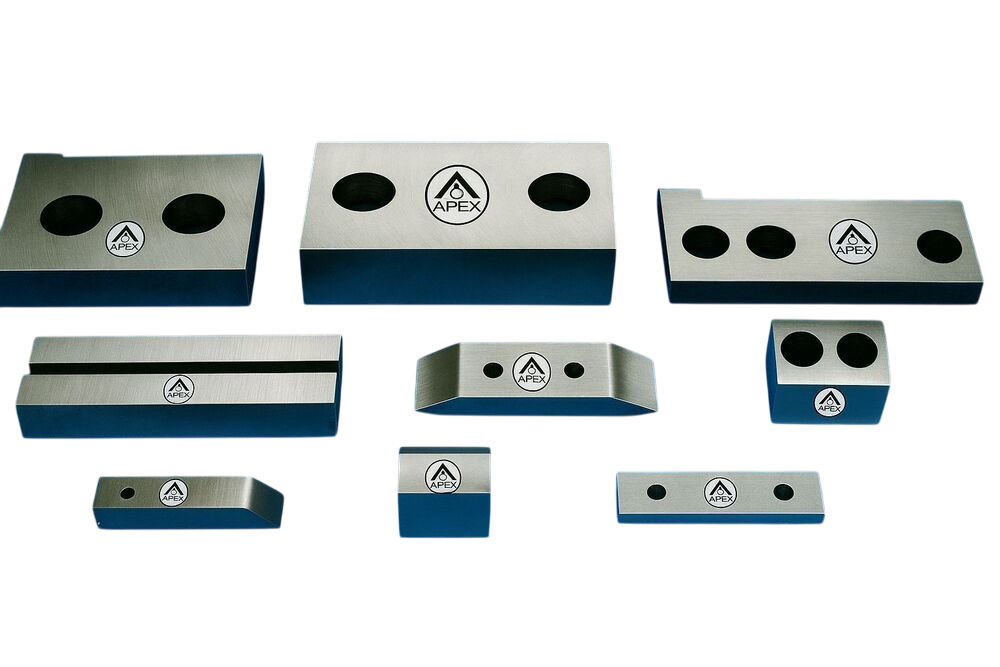

Hot Saw Blades

Product Details:

- Material Others

- Usage Industrial

- Size 700 mm

- Product Type Hot Saw Blades

- Click to View more

Hot Saw Blades Price And Quantity

- 1 Set

- 65000 INR/Set

Hot Saw Blades Product Specifications

- 700 mm

- Others

- Hot Saw Blades

- Industrial

Hot Saw Blades Trade Information

- DELHI

- 20 Set Per Week

- 8-10 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- WOODEN CASES

- All India

- INTERNAL ZERO DEFECT

Product Description

Hot Saw Blades are specialized cutting tools in the industry meant to cut red-hot metals in the primary and secondary steel processing. They have wide application in the rolling mills and steel plants where the metals pieces are to be cut right after rolling and when the temperature of these metals is very high. Hot Saw Blades are designed to work under extreme thermal and mechanical pressure, and provide a high degree of accuracy, speed and reliability in business-wide production.

Hot Saw Blades are made using alloy steels of high grade and processed using the latest metallurgical techniques, which ensure high resistance to heat fatigue, deformation, and surface cracking. Their high rigidity and optimum geometry enable them to retain their dimensions as well as cutting efficiency even in extensive exposure to high temperatures. These blades are important in ensuring production continuity, as well as reducing downtime in hot cutting process.

Application Scope and Functional Use

Hot Saw Blades are mostly intended to cut hot billets, blooms, slabs, railways and structural section directly off the rolling lines. These blades are very common in steel rolling mills, integrated steel plants, rail production units and heavy engineering industries. They can cut metal at higher temperatures hence minimized the secondary cutting processes, improved the speed of production and overall efficiency of operations.

Material Selection and Heat Resistance Properties

The blades are produced with the specially designed alloy steels that can resist high thermal loads. The material make up is meticulously chosen to offer high level of resistance to oxidation, thermal shock, and wear due to incessant contact with red-hot material. High heat treatments are done to increase the hardness of the blade and still maintain enough toughness to ensure a blade is not cracked or distorted. Such a balance guarantees longer blade life, uniform cutting behavior and fewer replacement intervals, even in the extreme demanding operating conditions.

Design Accuracy and Operational Stability

Hot Saw Blades are finely machined in order to obtain the desirable flatness, concentricity and balance. Machining has to be accurate and there must be strict control of dimensions to permit smooth rotation at high speed and assure consistent engagement with hot metal sections. The blade is shaped in a manner that provides consistency in the cutting motion and minimum vibration. This leads to fewer material wastages, less strain on cutting machinery and cleaner cuts. Their design allows them to operate continuously without their safety or performance being impacted.

Reliability in Harsh Industrial Conditions

Hot Saw Blades were designed to operate in severe steel plant conditions, and they exhibit a steady operation under the conditions of continuous thermal cycling and heavy loads. Their construction made them strong and reduced the chances of an abrupt blade break and thus their operations and schedules of production can be anticipated to be safe. These blades have high durability which means that they have better uptime and reduced maintenance expenses.

Manufacturing Standards and Inspection Process

The process of production starts with the certification of raw materials, after which the process proceeds to the forging or blank preparation. Precision machining gives the necessary accuracy of dimensions and finish. Directed heat treatment increases heat and mechanical stress resistance. A thorough quality inspection procedure is undertaken on each blade and it includes checking of hardness, checking dimensions, checking of balance and also checking the surface. These are measures that would ensure that all Hot Saw Blades are of high standards of performance and safety in industry.

FAQs:

What is the primary use of Hot Saw Blades?

They cut hot metal immediately after rolling; these include billets, blooms and rails.

Is it possible to use Hot Saw Blades in continuous high temperature?

Yes, they are specifically made to work in extreme heat and not to lose power or shape.

Do these blades enhance the efficiency of production?

Hot cutting does indeed remove some additional processing steps and enhances throughput.

Can they be customized?

They are also designed in many sizes and specifications to meet the various rolling mill needs.

What are the popular industries that utilize Hot Saw Blades?

Heavy engineering plants, rail manufacturing units and steel rolling mills are some of the popular industries where they are used.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+